Industry Insider: The Three Non-Negotiable Standards for A Premium Down Blanket

Views: 159 Author: changzhou haige Publish Time: 2025-12-02 Origin: changzhou haige

Introduction: Why Do Some Blankets Fail at 32°F?

Many campers focus on price and branding, often missing the core technical specifications that define true performance. As a specialized down gear manufacturer, we understand that conquering 0°C (32°F) requires adherence to strict standards in material science and construction.

Here is the essential, knowledge-based guide to the three factors that determine a down blanket's success in the field.

Part 1: The Engine – Down Quality & Ethical Sourcing

The performance of the blanket starts with the purity and efficiency of the insulation itself.

| STANDARD | TECHNICAL REQUIREMENT | MANUFACTURING GUARANTEE |

| 1. Efficient Fill Power (FP) | 650 FP is the industry sweet spot—balancing compression, loft, and warmth-to-weight ratio for optimal camping utility. | Strict batch testing to ensure FP meets or exceeds the stated rating, providing reliable, consistent warmth. |

| 2. Ethics & Hygiene | Down must meet stringent standards like RDS (Responsible Down Standard), paired with advanced cleaning for safety. | We ensure ethical sourcing and implement high-pressure steam sterilization to deliver clean, odor-free, allergy-safe materials. |

Part 2: The Armor – Shell Technology & Construction

The shell fabric is the unsung hero, protecting the down and maximizing its lifespan.

✅ Critical Shell Specs:

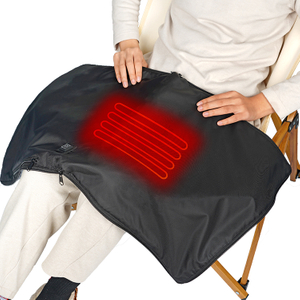

DWR Coating: (Durable Water Repellent) This is non-negotiable. The DWR treatment must be high-grade to bead off dew and moisture, preventing saturation and preserving the down's loft.

Fabric Density: We mandate high-density nylon (e.g., 20D-30D) to balance minimal weight with high tear resistance, effectively locking the down in place.

️ Construction Integrity: Eliminating Cold Spots

Precise Baffling: Quality manufacturing uses advanced stitching to create uniform baffles (chambers). This prevents down migration, ensuring even distribution and zero cold spots across the entire blanket surface.

Part 3: Smart Design – Utility for the Modern Camper

A premium blanket must be engineered for versatility, making the user's load lighter and their experience smoother.

Poncho Convertibility (Snaps): Edge snaps are not a gimmick; they are critical for instant utility, allowing the user to wear the blanket hands-free while performing camp chores.

Optimized Compression: The design must prioritize compressibility. The final product should easily pack into a small stuff sack, ensuring minimal volume in the customer’s backpack.

Conclusion: Trust the Standards

A high-performance down blanket is a commitment to technology, quality materials, and precise manufacturing. When evaluating gear, always prioritize these three standards over simple marketing claims.

Choosing products manufactured to these specifications means investing in an outdoor experience that is lighter, more efficient, and worry-free.